Trowel Polishing

The Fastest and Most Cost-Efficient Way to Polish Large Industrial Floors.

Advantages of Trowel Shine

-

High Productivity, Better Efficiency

You can easily cover 10,000 sqf/hour per step with a standard six-foot trowel, which translates into a significant time and cost savings compared to traditional polishing.

-

Universal Application & Versatility

You can use Trowel Shine pan system with almost any ride-on power trowel and customize your polishing setup. Trowel Shine uses the same tools as LAVINA Grinders, including metals, resins and maintenance pads.

-

Less Maintenance, More Savings

Trowel Shine features encapsulated bearings protected from slurry and damage. The hub of our holders is pre-greased and comes with pressed-in bearings, races, and grease seal installed, so there is no need for periodic re-greasing or inspection.

How-To Trowel Shine

Trowel Shine Polishing is done WET, which means you will need to manage and dispose of the slurry.

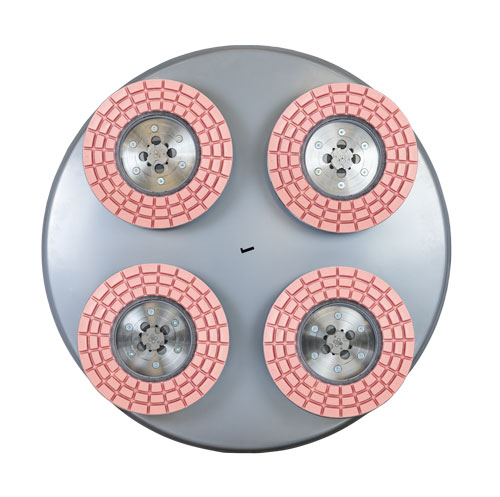

TOOL HOLDERS

We offer two options to set up your trowel pans for trowel polishing:- 10.63″ Foam Heads with velcro attachment #P02-FP-10.63 for use with velcro-backed tools. Can be also used with Suprashine maintenance pads.

- 13.2″ Metal Heads with QuickChange attachment #A95.00.00-2 for use with Quick Change tooling, metals and resins (attach security plates to lock tools in place). Can be also used with Suprashine maintenance pads (via pad holder #A87.00.00R.

CUSTOMIZED PANS

We can supply different diameter pans with pre-installed tool holders based on your trowel specs. Or, you can install the heads / plates on your own pans. Each tool holder comes with a template and instructions to help you install it correctly.

We recommend matching the number of tool holders to the number of trowel blades (example – install 4 tool holders on power trowels with 4 blades).

TOOLS for Grinding

On flat floors / new construction you can start with Waffel Resins, 50 grit (Wet bond).

If grinding is necessary (damaged concrete, rain drop effect, etc), use the SA-Superthick METAL discs, offered in 46, 70, 120 grit.

Follow with HD Copper, 50 and 100 grit, to remove scratches and transition to resins. Or, you can use Waffel Resins 120 grit, Wet Bond instead.

TOOLS for Polishing

Continue with Waffel Resins, 220 and 400 grit, Wet Bond.

After 400 or 800 grit, you can switch to V-Harr polishing pads, or SupraShine HP Pads. To attach SupraShine (or other maintenance pads) to the 13″ metal heads, you need pad holders #A87.00.00R (see Accessories page).

We now offer SupraShine pads in 36″ and 48″ size for use with trowel pans. They can be attached directly to the pans with velcro strips, no tool holders needed, for incredible savings.

Optimize your large polishing projects.